about us.

We are specialized in stainless steel processing of metal plates, profiles and pipes.

Biotechnik is an economically viable service provider:

Stainless steel products and equipments are manufactured for good prices, the focus lies on time-intensive executed parts.

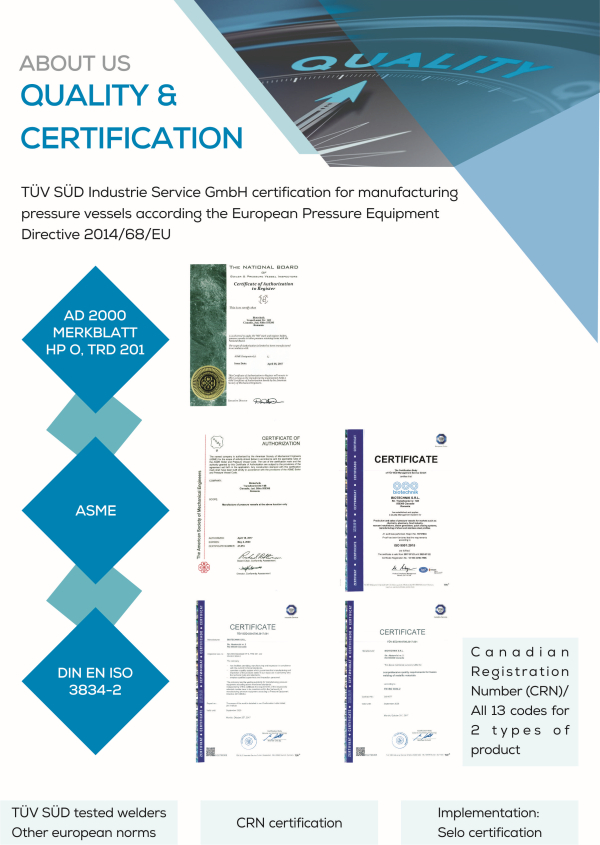

Already in 1994, we were certified for manufacturing equipment according to the Pressure Equipment Regulation by the TÜV Bayern. We are now reviewed by TÜV SÜD Industrie Service GmbH as manufacturer according to the AD 2000-Merkblatt HP 0, TRD 201 and EN ISO 3834-2 and certified for the production of pressure equipment according to the European Pressure Equipment Directive 2014/68/EU.

Services

Design

Execution of projects and resistance calculations for PED and ASME authorization.

Mechanical processing

Mechanical processing by turning, milling, water jet cutting, mounting, etc.

Welding

WIG welding, MIG-MAG, spot welding, manual, mechanized and automatic with specialized robots.

Electropolishing

Electrochemical polishing to obtain mirror gloss.

Sandblasting with glass pearls

Sandblasting with special glass pearls for stainless steel.

Pickling and passivation

Necessary after welding the stainless steel.

NDT

Non-destructive test of welds performed by RX, US, gamma rays, penetrating liquids, etc. through our collaborators.

Inspection by Notified Body

We host the inspection of the authorized body for the pressure vessels and the pressure test of the executed vessels.

Quality

Projects Completed

Satisfied Clients

Positive Feedbacks

Delivery evolution

Our Machinery

Water-jet cutting

Using a thin high-pressure jet – a simple and very efficient separating technique for many materials

The materials are separated by means of a high-pressure jet using pressure of up to 4,300 bar and a water-jet speed of up to 800 m/s. In case of hard materials, e.g. stainless steel, the water jet is combined with an abrasive, namely fine sand, so that the bonded material is separated. Due to this, a fissure size of less than 1 mm is possible, even when working with thick sheets.

ABKANT CNC320T

High capacity bending machine with CNC control for the production of bent pieces, thin and thick sheet with precise dimensions.

Rolling Machine

Bending machine profiles and pipes for making round and spiral parts.

Electropolish

Electropolished and mechanically produced metal surfaces have fundamental differences. Mechanical operations such as lathing, drilling, grinding and polishing will all adversely affect the structure and properties of the material surface. Contamination resulting from tool abrasion and contact with coolants can lead to corrosion and wear. Dependent upon the degree of the manufacturing forces applied, the surface structure can be affected to a depth of 50 microns.In contrast to this, electropolishing will removed metal from the component without any mechanical, thermal or chemical transformation. Electropolishing will eliminate damaged surface layers and allow the original properties of the material to be fully utilised again.